The Future of Concrete: Innovations and Trends to Watch

Concrete, a fundamental element of modern construction, has long been the bedrock of our built world. Its strength and versatility have supported countless structures, from highways to skyscrapers. Yet, as our world changes, so does the construction industry, ushering in a wave of innovation and sustainability.

Let’s explore the evolving landscape of concrete technology and the trends shaping its future. To illustrate these developments, we’ll highlight National Concrete Polishing, a company leading the charge in concrete innovation. They specialize in concrete polishing, turning ordinary surfaces into extraordinary showcases of art and engineering. As we dive into the innovations and trends ahead, National Concrete Polishing exemplifies a commitment to reimagining what concrete can be.

Join us on this journey through the future of concrete, where sustainability, advanced mixtures, smart applications, 3D printing, nanotechnology, and augmented reality converge to reshape construction as we know it. Discover the transformative potential of concrete and the exciting possibilities on the horizon.

Sustainable Concrete

Exploring the environmental impact of traditional concrete

Traditional concrete, while exceptionally strong and versatile, exacts a toll on the environment. The production of Portland cement, a primary component of concrete, is energy-intensive and emits a significant amount of carbon dioxide (CO2) into the atmosphere. Additionally, mining for aggregates and transportation of materials contribute to resource depletion and pollution. As the construction industry recognizes the environmental challenges, it is imperative to explore sustainable alternatives to traditional concrete.

Sustainable concrete and its benefits

Sustainable concrete, also known as eco-friendly or green concrete, represents a paradigm shift in construction practices. It aims to mitigate the environmental impact of concrete while maintaining its structural integrity. The primary benefits of sustainable concrete include reduced carbon emissions, decreased resource consumption, and a smaller ecological footprint. Sustainable concrete aligns with the broader goal of constructing responsibly for the well-being of our planet.

Innovations in sustainable materials (e.g., recycled aggregates, low-carbon cement)

Innovations in sustainable concrete materials are key drivers of its adoption. These materials reduce the reliance on traditional, resource-intensive ingredients. Recycled aggregates, sourced from reclaimed concrete or other materials, minimize the need for virgin aggregates, thus conserving resources. Low-carbon cement formulations aim to lower the carbon footprint of concrete production. The integration of these innovative materials is crucial in advancing sustainable concrete solutions.

Case studies of sustainable concrete projects

To illustrate the practical application of sustainable concrete, let us examine case studies of noteworthy projects. These projects showcase how sustainable concrete can be used effectively in real-world scenarios. From eco-friendly residential buildings to environmentally conscious infrastructure, these examples demonstrate the versatility and efficacy of sustainable concrete solutions. National Concrete Polishing’s involvement in such projects underscores their commitment to environmentally responsible construction practices.

Advanced Concrete Mixtures

The importance of concrete mix design

The backbone of any successful concrete project is the mix design. Concrete mixtures are carefully crafted to meet specific requirements for strength, durability, and other properties. Achieving the right mix is essential for the long-term performance of concrete structures. National Concrete Polishing’s meticulous attention to detail in their projects highlights the critical role of mix design in achieving desired outcomes.

High-performance concrete (HPC) and its applications

High-performance concrete, or HPC, is a remarkable advancement in concrete technology. It offers exceptional strength and durability, making it ideal for a wide range of applications. From high-rise buildings to critical infrastructure projects, HPC plays a pivotal role in achieving structural excellence.

Self-healing concrete represents a groundbreaking innovation in the field. It has the ability to autonomously repair micro-cracks that form over time. This not only enhances the lifespan of concrete structures but also reduces the need for costly maintenance and repairs. Self-healing concrete’s potential underscores its role in improving the longevity and sustainability of concrete surfaces.

Lightweight and ultra-high-strength concrete

Lightweight and ultra-high-strength concrete formulations are changing the way concrete is used. Lightweight concrete offers advantages in terms of reduced dead load and improved insulation properties, making it suitable for a variety of applications. On the other hand, ultra-high-strength concrete achieves extraordinary compressive strength, opening doors to innovative and daring architectural designs. National Concrete Polishing’s involvement in projects utilizing these advanced concrete mixtures exemplifies their commitment to staying at the forefront of concrete technology.

Smart Concrete

The concept of smart concrete and its role in the future

Smart concrete represents an exciting frontier in construction technology. It goes beyond the traditional role of concrete as a passive building material and transforms it into an active component that can sense, monitor, and respond to changes in its environment.

Self-sensing and self-monitoring concrete

Smart concrete is equipped with sensors and monitoring systems that allow it to detect changes in temperature, stress, strain, and even structural integrity. It can alert engineers and stakeholders to potential issues before they become critical, enhancing safety and reducing maintenance costs. National Concrete Polishing’s commitment to innovation extends to the adoption of smart concrete technologies, ensuring their projects are at the forefront of structural health monitoring.

Applications of smart concrete in infrastructure and buildings

The applications of smart concrete are diverse and far-reaching. From bridges and highways to commercial and residential structures, smart concrete can provide real-time data on the condition and performance of construction materials.

The integration of IoT technology with concrete

The integration of the Internet of Things (IoT) technology with concrete is a pivotal aspect of smart construction. IoT sensors embedded in concrete structures communicate data to centralized systems, enabling remote monitoring and predictive maintenance.

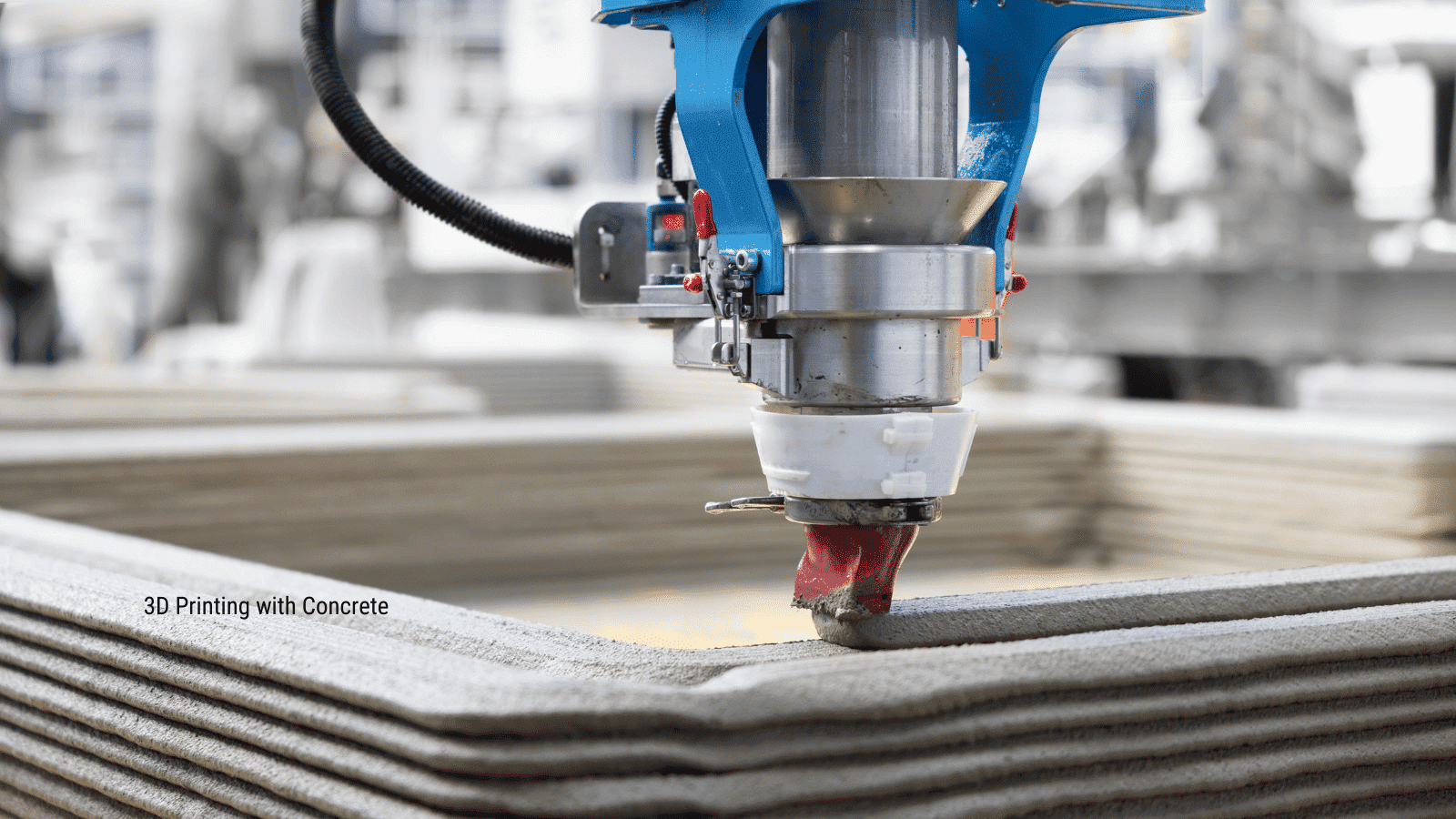

3D Printing in Construction

The emergence of 3D printing in construction

3D printing has emerged as a disruptive force in construction, offering a revolutionary approach to building. 3D printing in concrete construction offers unparalleled precision and efficiency. It enables the rapid creation of complex concrete structures with reduced material waste. We’ll delve into the ways 3D printing is transforming the construction landscape, making it possible to create intricate and innovative designs with ease.

Examples of 3D-printed concrete structures

Concrete 3D printing has already produced impressive real-world examples. From houses and bridges to artistic installations, notable 3D-printed concrete structures, there is concrete evidence of the technology’s potential and versatility.

Future prospects and challenges of 3D printing in concrete

As 3D printing in concrete gains momentum, it faces both promising opportunities and significant challenges. The prospects of this technology, including its potential to reduce construction timelines and costs, also come with hurdles that need to be overcome, such as scalability and material development, to fully realize its potential in the construction industry.

Decorative Concrete: Elevating Aesthetics in Construction

Decorative concrete is a versatile tool for enhancing the visual appeal of structures. It offers a wide range of design possibilities, including stamped, stained, and polished finishes, allowing for creative expression in both indoor and outdoor spaces.

Beyond aesthetics, decorative concrete contributes to sustainability by reducing the need for additional materials and providing thermal mass properties that enhance energy efficiency. It’s a fusion of beauty, functionality, and eco-consciousness in the world of modern construction.

Future Challenges and Considerations

In the realm of concrete innovation , a promising future beckons, but it is not without its challenges and considerations. These hurdles must be acknowledged and surmounted to pave the way for these innovative technologies to become standard in the construction industry.

Identifying Potential Obstacles to Implementing These Innovations

The innovations we’ve explored hold significant promise, but they may encounter resistance to change within the construction industry. The familiar ways of doing things can be difficult to depart from, and the initial costs and required specialized skills may pose hurdles. Overcoming these obstacles will be crucial in mainstreaming these innovations.

The Importance of Standards and Regulations in the Concrete Industry

As concrete technology advances, maintaining stringent standards and regulations becomes paramount. Ensuring the safety and quality of construction materials and practices is non-negotiable. Industry standards play a pivotal role in guaranteeing the reliability and performance of innovative concrete solutions. They serve as the bedrock upon which these innovations can thrive.

Balancing Innovation with Sustainability and Safety

Innovations in concrete must strike a delicate balance between pushing boundaries and adhering to sustainable and safety principles. Sustainable concrete solutions should not compromise environmental responsibility, and safety should remain a top priority. Finding this equilibrium is essential for the responsible progression of innovation in the field.

Future Directions and Areas for Further Research

The concrete landscape continues to evolve, and there are promising avenues for future research and development. These include refining sustainable materials, expanding smart concrete applications, and optimizing 3D printing techniques. The construction industry will remain a hub of innovation, and these areas represent the compass guiding our future endeavors.

As we conclude our exploration of the dynamic world of concrete innovation, we are left with a profound sense of possibility and potential. We’ve seen how pioneers like National Concrete Polishing are pushing the boundaries, contributing to a more sustainable, efficient, and durable construction industry.

The innovations and trends we’ve traversed are indicative of an industry committed to improving sustainability, efficiency, and safety. While there are challenges to overcome, the promise of a brighter future for concrete is undeniably exciting.

In a world that constantly evolves, staying informed about concrete innovations is not a choice but a necessity. Architects, engineers, builders, and construction professionals must continue to collaborate, share knowledge, and wholeheartedly embrace these innovations. Together, we are poised to shape a future where concrete remains the cornerstone of our built environment, while also evolving into a dynamic, adaptable, and environmentally responsible material. Contact us at National Concrete Polishing as we lead the way, we embark on this journey with optimism, confident in the transformative potential of concrete in the years to come.

You might also like

Book a Service Today

We will get back to you as soon as possible

Please try again later

Satisfied Clients

"Jon fixed some flooring issues that I couldn't handle on my own. He was professional, courteous and worked quickly."

MIKE T.

Button

"Adam showed up on time, did the job quickly, and was polite and professional. Would definitely use again."

SHANNON W.

Button

Quick & Reliable

We are available 24/7 via live chat, email or telephone

We proudly use and sell the following products and equipment

We proudly serve the following cities and counties throughout the Charlotte North Carolina area and beyond.

Concord – Gastonia – Kannapolis – Monroe – Mount Holly – Belmont – Tega Cay – Kings Mountain - Charlotte - Rock Hill - Huntersville - Mooresville

Hickory - Indian Trail - Salisbury - Cornelius - Fort Mill - Matthews - Statesville - Mint Hill - Waxhaw - Shelby - Harrisburg - Mount Holly

Get a Quote

We will get back to you as soon as possible

Please try again later

All Rights Reserved - Need a lead generating website like this? Contact the webmaster